Cobalt Chrome Screws (CoCr)

Increased Strength and Precision With CoCr Screws

Titanium alloy (Ti) hexalobe screws from Acumed are a standard in upper and lower extremity applications, leading to over 4.5 million successful implants globally. However, certain patients with high bone density or complex fractures may require alternative materials that are more suitable than Ti.

Acumed’s CoCr screws are an ideal solution by providing improved ease of screw insertion and removal, and increased screw strength. They have also been tested to be biologically compatible to use with Ti plates.1

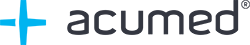

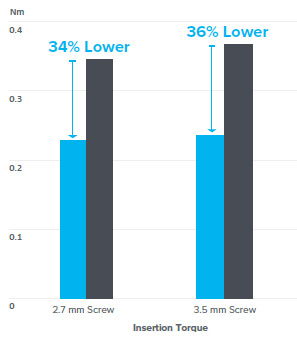

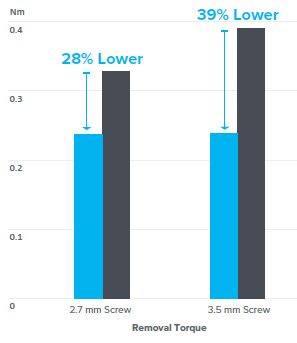

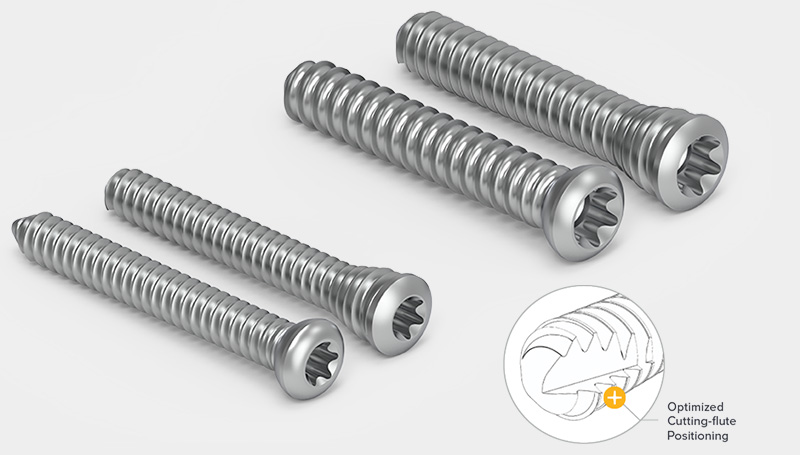

Improved Ease of Insertion and Removal

An improved cutting-flute design makes implant placement and removal quicker and easier. This may lead to reduced procedure times and minimal surgical trauma.2

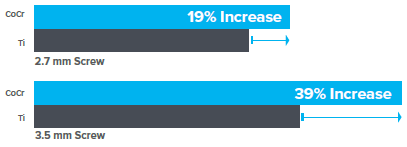

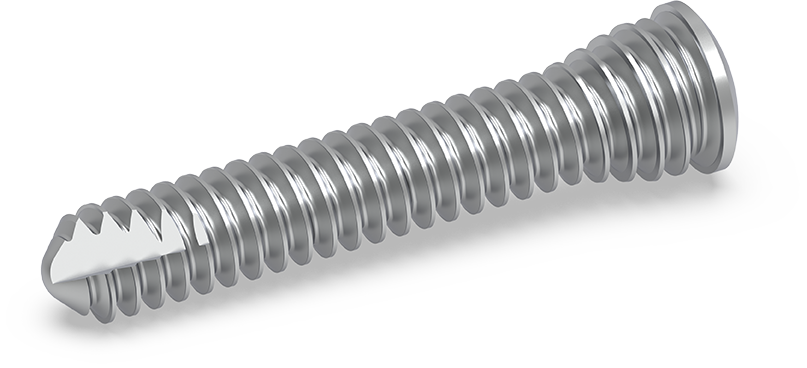

Increased Strength

Due to material and manufacturing process improvements, CoCr screws can withstand greater rotational torque without breaking or stripping compared to Ti screws, which may be beneficial for patients with dense bone.1

Biological Compatibility

Extensive testing has shown our CoCr screws to be biologically safe to use with Ti plates with no appreciable galvanic corrosion occurring between the two materials.1

Galvanic Corrosion Testing

The 2.7 mm and 3.5 mm screws included in various Acumed systems are composed of cobalt chrome (CoCr) alloy and are used with Acumed plates consisting of titanium alloy and commercially pure titanium.

Dissimilar metals in contact in an electrolyte solution may initiate an electrochemical process known as galvanic corrosion, where one metal corrodes another as a result of an electropotential difference between the metals.3 Galvanic corrosion manifests as accelerated corrosion of the more active, corroding metal (anode), and slower corrosion of the more noble metal, if it corrodes at all.3

There is significant research on the safe use of CoCr and titanium in the body. Both CoCr and titanium are self-passivating, indicating that these materials tend not to have galvanic interactions over time.3 Kummer et al previously demonstrated that CoCr-titanium couples result in low, stable galvanic currents that gradually decrease over time.4 A number of orthopaedic device manufacturers are currently using CoCr screws and titanium plates in the same combination as Acumed.

In order to quantify the potential impact of galvanic corrosion on Acumed’s CoCr, third-party testing was completed. The corrosion rate and mass loss for each sample couple was determined and used to calculate material release.

Summary of Galvanic Couple Current Data for Screw Platform Materials (CoCr, Titanium Alloy, Commercially Pure Titanium)

Corrosion Rate (CR) Mils Per Year (mpy)3

Mass Loss (MR)

(μg/cm2/day)

Calculated Material Release (μg/day)

The calculated corrosion rate (CR) was less than 0.001 mpy. The MR was less than 0.04 μg/cm2/day. For these cobalt chrome screws, with a surface area of 1.63 cm2, this translates to less than 0.07 μg/day of cobalt-chrome material released.

In addition to the corrosion rate, mass loss, and calculated material release, the cobalt-chrome screws were examined pre- and post- testing at up to 40X magnification to assess their general condition. This examination revealed no pitting or indication of corrosion.

Acumed’s findings are consistent with those in the research literature that showed that CoCr and titanium alloys generate a finite current, ultimately resulting in a stable passive film, limiting material loss to nearly undetectable levels.4 It has been verified that no appreciable galvanic corrosion occurs between CoCr screws and Ti plates.

1. Data on File

2. Yerby, et al. Effect of Cutting Flute Design on Cortical Bone Screw Insertion Torque and Pullout Strength. J Orthop Trauma. 2001;15(3):216–221.

3. Urish K, Anderson P, Mihalko W and the AAOS Biomedical Engineering Committee. The challenge of corrosion in orthopaedic implants. AAOS Now. April 2013.

4. Kummer FJ, Rose RM. Corrosion of titanium/cobalt-chromium alloy couples. J Bone Joint Surg Am. 1983 Oct;65(8):1125-6.

*The combined usage of CoCr screws and Ti plates is stable and determined to be mechanically and biologically safe. Data on file.